BMS Battery: The Ultimate 2025 Guide to Principles, Selection, Wiring & Troubleshooting

Whether you’re designing an EV pack, a mobility scooter, or a residential storage cabinet, the bms battery (Battery Management System + pack) is the control tower for safety, lifespan, and performance. This hands-on guide explains how a BMS works, how to select one that truly fits your project, how to wire it correctly, and how to debug the common pitfalls.

- What is a bms battery?

- Core Functions: Protection, Balancing, Estimation, Comms, Thermal

- Architectures & Topologies: Centralized / Modular / Distributed

- Selection Checklist: What to Look For (Engineer’s View)

- Wiring & Commissioning: 8 Practical Tips

- Troubleshooting: Over-voltage, Under-voltage, False SOC

- FAQ: Your Most Common Questions

- Get a Tested Solution

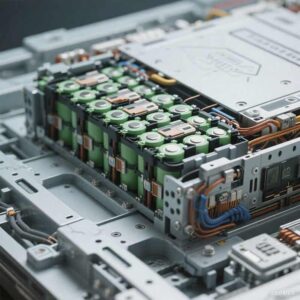

1) What is a bms battery?

A bms battery is the combination of a battery pack and its Battery Management System. The BMS monitors cell voltages and temperatures, controls charge/discharge via protection MOSFETs or contactors, performs balancing, estimates SOC and SOH, communicates with the rest of the system, and enforces thermal limits. Without a BMS, modern lithium packs are blind and unsafe. With a good BMS, you can extend lifespan and keep performance predictable.

Applications range from e-bikes, scooters and mobility aids to EV conversions, AGVs, forklifts and residential/industrial energy storage. The higher the power and voltage, the more critical your BMS selection becomes.

2) Core Functions & How They Work

- Protection: single-cell and pack OVP/UVP, charge/discharge over-current, short circuit, high/low temperature; fast acting and configurable thresholds.

- Balancing: passive (resistive) balancing is simple and robust; active balancing transfers energy between cells for faster equalization and improved efficiency.

- Estimation: SOC, SOH and SOP using coulomb counting, open-circuit-voltage curves, temperature compensation and filtering algorithms.

- Communication: CAN/RS485/UART to the vehicle controller, charger, HMI or cloud; fault codes and real-time telemetry.

- Thermal management: temperature sensors drive derating, charge current limits and cooling control; cold-charge protection is essential for Li-ion.

- Data & logging: cycle count, event logs, diagnostics and OTA updates for long-term reliability.

3) Architectures & Topologies

| Type | Pros | Cons | Best for |

|---|---|---|---|

| Centralized | Cheaper, simpler wiring; good for low–mid series count. | Less scalable; long sense lines can be noisy. | E-bikes, scooters, small carts, 12–24S packs. |

| Modular | Better EMI, easy module swap, good diagnostics. | Higher cost and complexity than centralized. | Mid/large packs, commercial EVs, industrial storage. |

| Distributed | Shortest harness, best per-cell data, strong scalability. | Most complex and costly; challenging commissioning. | High-voltage platforms, utility storage, performance EVs. |

4) Selection Checklist (Engineer’s View)

- Series count (S) & chemistry: LFP vs. NCM/NCA have different OCV and limits—don’t reuse thresholds blindly.

- Continuous / peak current: size with at least 20–30% headroom; check peak duration and thermal limits.

- Protection thresholds & hysteresis: OVP/UVP, charge/discharge overcurrent, short-circuit, high/low temp, recovery rules.

- Balancing: passive is fine for most; consider active for high-capacity/fast-charge or poorly matched cells.

- Comms protocol: CAN (DBC), RS485/Modbus, BLE/4G—match the charger/VCU/HMI exactly.

- Sensing accuracy: voltage/temperature precision drives SOC convergence and balancing effectiveness.

- Logs & tools: event history, parameter import/export, OTA; good PC/mobile tools save weeks of work.

- Safety & compliance: UN38.3, IEC, E-mark/EEC (where applicable) for your market.

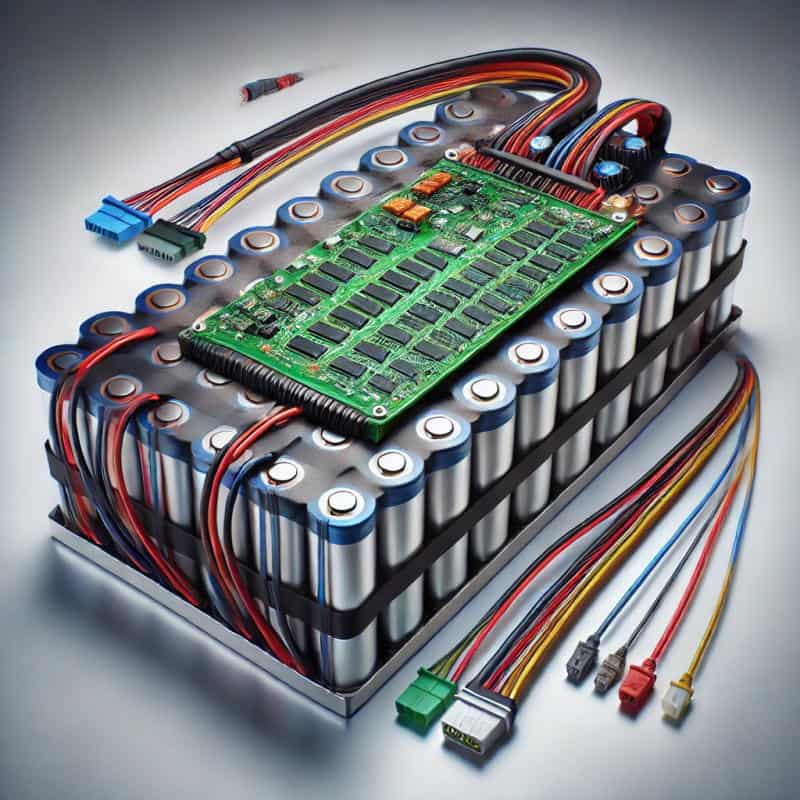

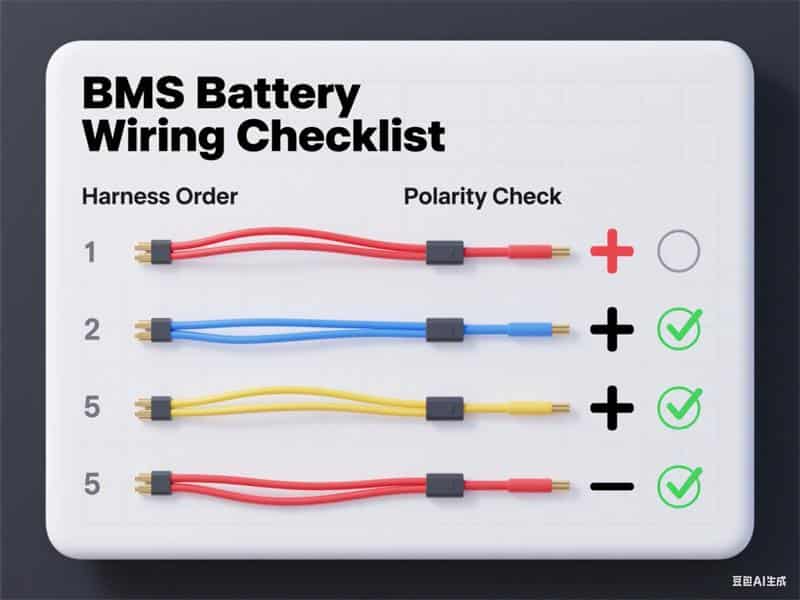

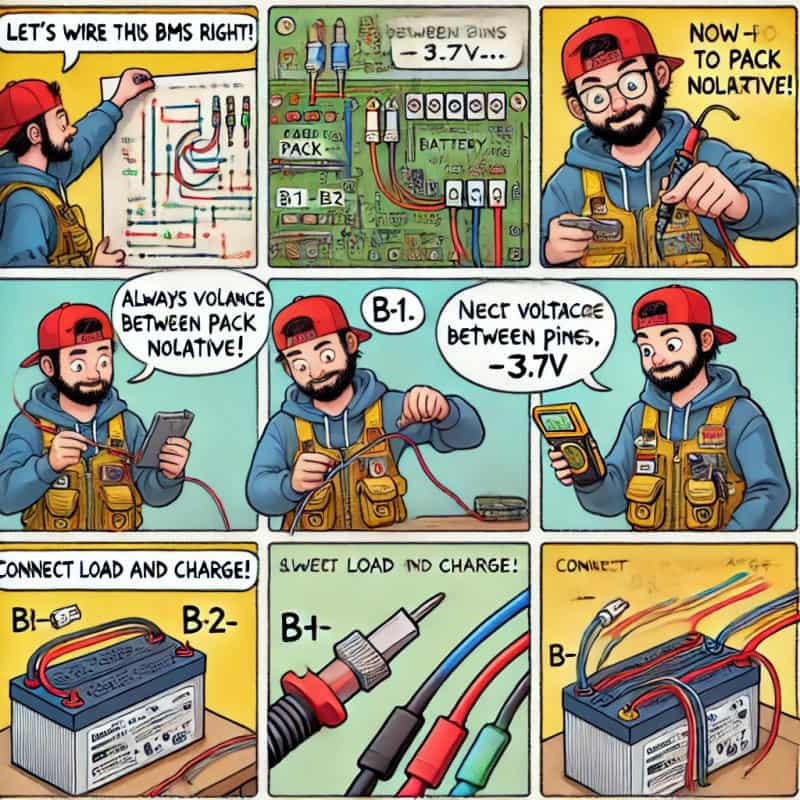

5) Wiring & Commissioning: 8 Practical Tips

- Order first: connect pack negative, then cell taps B1→Bn; never skip or reverse taps.

- Harness routing: keep sense lines away from high-current paths; avoid coils/loops.

- Polarity check: verify each series voltage with a DMM before energizing the BMS.

- Thermal coupling: secure temp sensors to representative hot cells/modules.

- Insulation & strain relief: deburr edges, add abrasion guards, strain relieve heavy connectors.

- Parameter set: import chemistry profile, tune thresholds and balance delta carefully.

- Low-power bring-up: start with limited current, confirm comms and protection logic.

- Log early: export logs at the first warnings/faults; tune once, document always.

6) Troubleshooting the bms battery

- Frequent OVP/UVP: check weak cells and thresholds; widen recovery hysteresis; increase balancing power if applicable.

- Balancing seems inactive: verify delta-V trigger and thermal limits; note that passive balancing is slow by design.

- False SOC: perform a full charge and rest calibration; validate OCV table; fix current sensor drift and temperature comp.

- Over-temperature: improve airflow/liquid cooling; derate or limit charge at high temps; avoid cold charging for Li-ion.

- Comms dropouts: check CAN termination and wiring; on RS485, verify A/B polarity; fix shielding and grounding.

7) FAQ

Q1: Can one BMS profile cover both LFP and NCM?

No. Use chemistry-specific thresholds, OCV tables and temperature rules. A generic profile often causes nuisance faults or premature aging.

Q2: Is passive balancing enough?

For most small/mid packs, yes. For large capacity, fast charging or poor matching, consider active balancing to speed up equalization.

Q3: How to stabilize SOC?

Recalibrate using a full charge + rest, verify current sensor accuracy, refine OCV curve and temperature compensation, and use filtering (e.g., Kalman variants).

Q4: What standards matter?

Depending on your market: UN38.3 for transport, IEC standards for safety/performance, and automotive approvals for on-road applications.

8) Get a Tested bms battery Solution

Send us your cell model, series/parallel count, target current, and comms protocol (CAN/RS485). We’ll review it and suggest a matching BMS + pack strategy.

*Always follow local codes and standards. Replace placeholders for internal links with your real URLs before publishing.